The manufacturing industry is on the brink of a transformation, and predictive analytics is the solution that can supercharge efficiency. AI is changing the world of predictive analytics and reshaping the manufacturing landscape.

Understanding Predictive Analytics

Before we dive into the practical applications, let’s clarify what predictive analytics entails. At its core, predictive analytics involves the use of data, statistical algorithms, and machine learning techniques to identify the likelihood of future outcomes based on historical data. In the manufacturing context, this means predicting equipment failures, production bottlenecks, and resource allocation needs with unprecedented accuracy.

The Mechanics of Predictive Analytics in Manufacturing

Predictive analytics in manufacturing is not a one-size-fits-all solution. It relies on complex algorithms and models tailored to specific processes and objectives. These models, powered by artificial intelligence (AI) and machine learning, analyse a manufacturer’s datasets, and consider factors like equipment performance, historical production data, and environmental conditions.

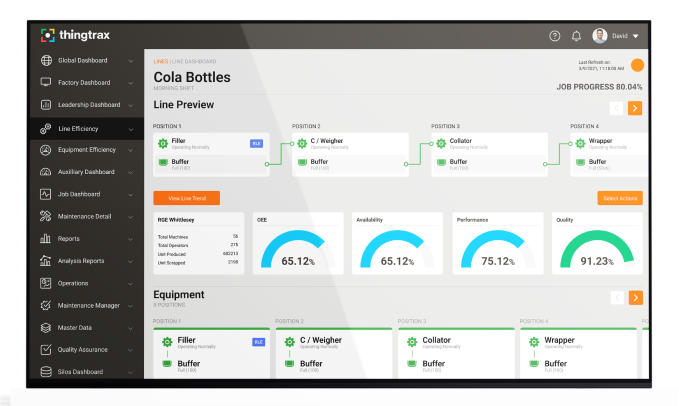

One key application is Predictive OEE (Overall Equipment Effectiveness) Per Shift. This involves assessing and predicting the efficiency and effectiveness of equipment during specific shifts or time periods. By analysing historical data and real-time inputs, manufacturers gain insights into when and where equipment might underperform, enabling proactive maintenance and minimising downtime.

The Benefits of Predictive Analytics in Manufacturing

So, why should manufacturers embrace predictive analytics? The benefits are multiple:

- Reliable Resource Allocation: Predictive analytics provides estimates based on factory performance, offering a more accurate picture of how long specific tasks or processes take. This precision reduces the risk of overestimating or underestimating production times, leading to more reliable project planning and resource allocation.

- Enhanced Customer Satisfaction: Meeting or exceeding promised delivery dates becomes more achievable with performance-based estimates. This enhances customer satisfaction and builds trust, which can lead to repeat business and an improved reputation.

- Reducing Idle Time: Estimating based on factory performance helps in creating realistic production schedules. This, in turn, enables better planning for production runs, reducing bottlenecks and idle time.

- Continuous Improvement: Over time, performance-based estimates can be used to identify areas where processes can be optimsed and made more efficient. This leads to ongoing process improvement initiatives, increasing overall productivity.

Now that you’re learned about AI-powered predictive analytics, stay tuned for Part 2, where we’ll reveal a dynamic, step-by-step guide to launching this transformative solution in your manufacturing ecosystem.

Embrace the future of manufacturing with Thingtrax Predictive Analytics. Get started today for smarter, more efficient operations.

SEEING IS BELIEVING

Book a free demo to understand how you can

- Gain instant visibility of performance and trends

- Seamlessly connect together every aspect of your production process, both digital and analogue

- Enable your workforce to take ownership for targets

During the call we’ll provide an overview on how Thingtrax’s customers use our platform to increase efficiency and reduce costs.