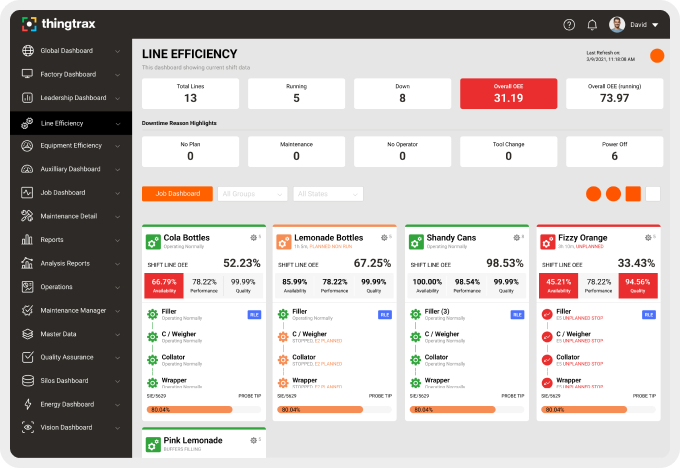

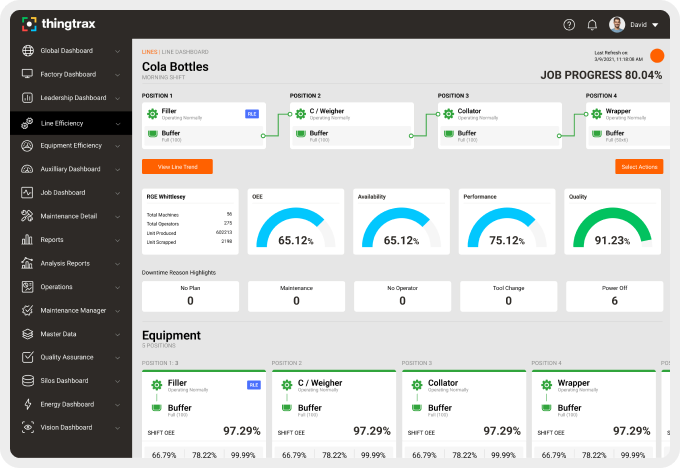

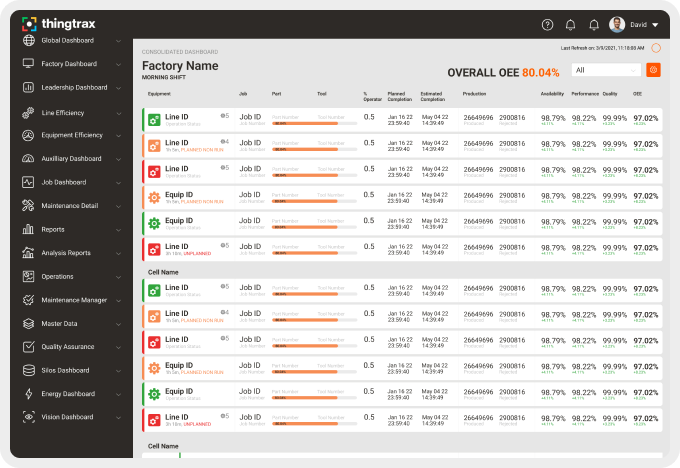

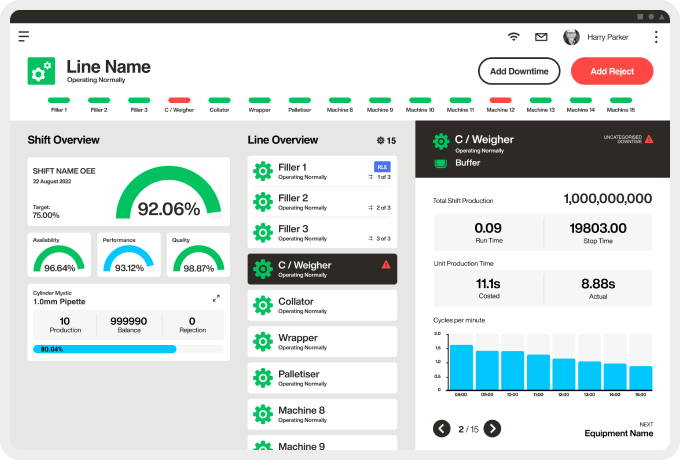

thingtrax’s Productivity Suite measures the pulse of your manufacturing operation. OEE is displayed in real-time, making it easy to understand where inefficiency exists.

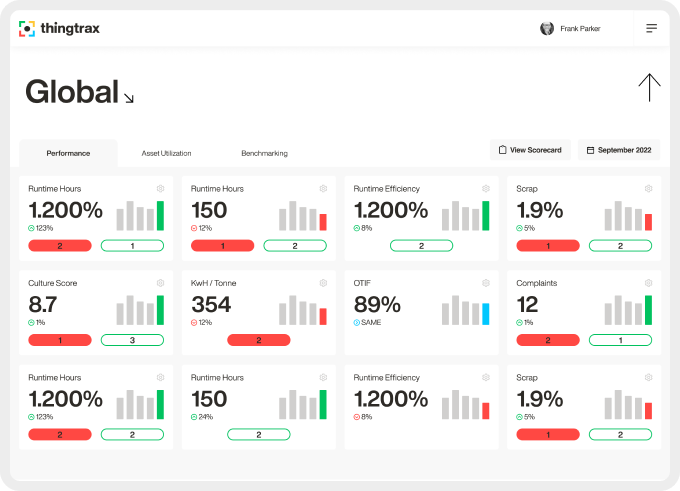

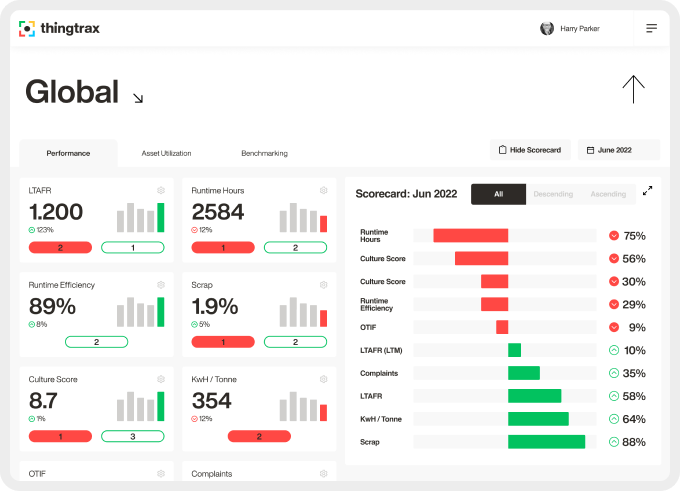

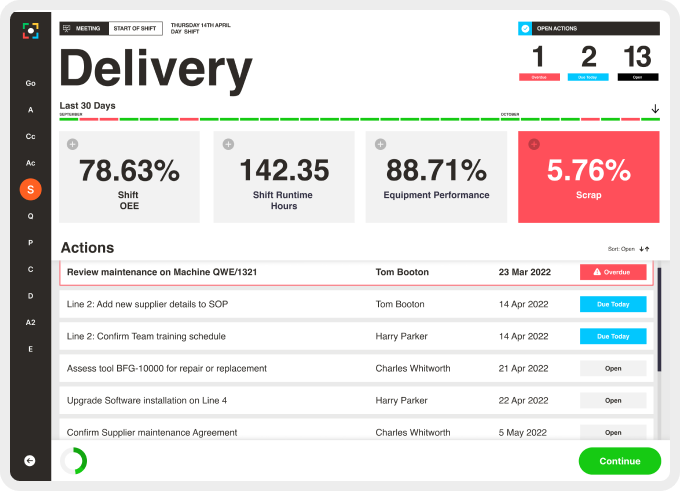

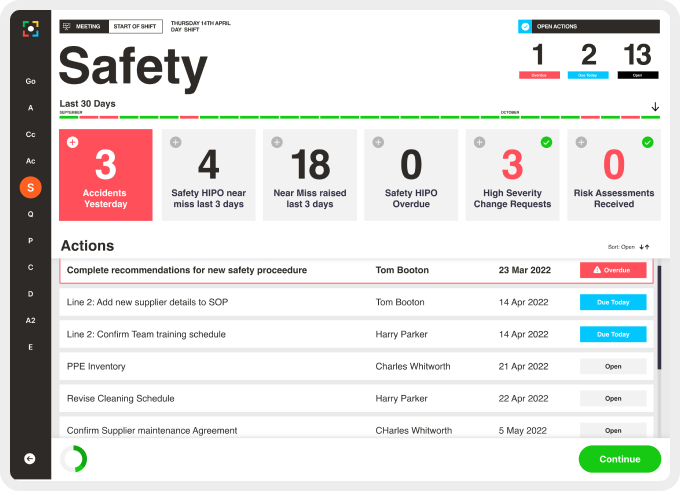

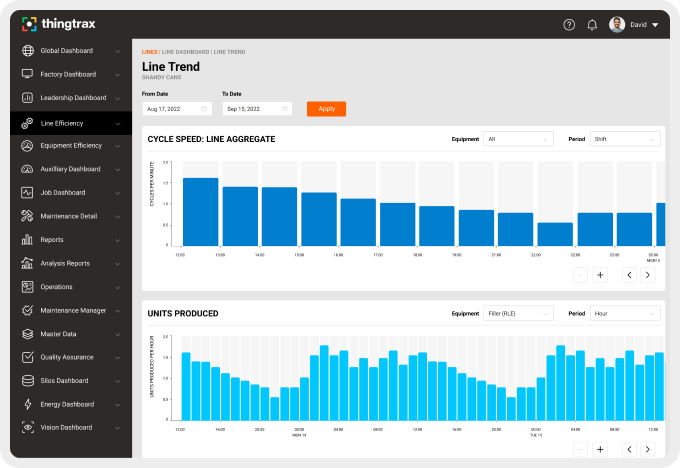

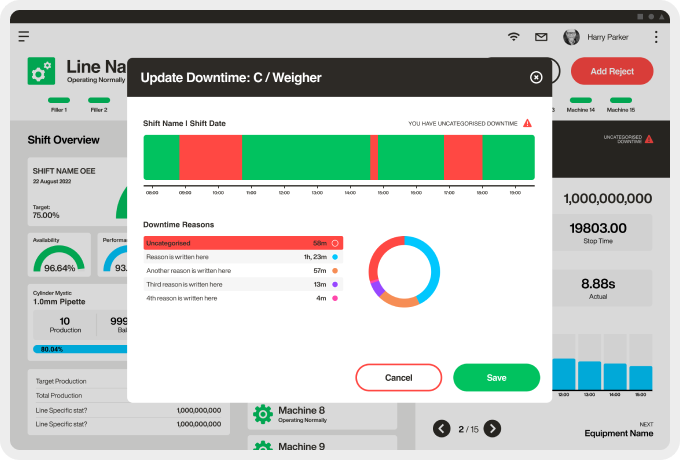

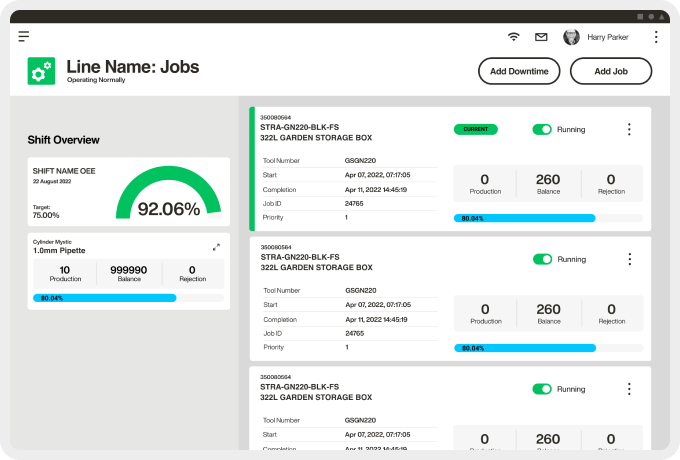

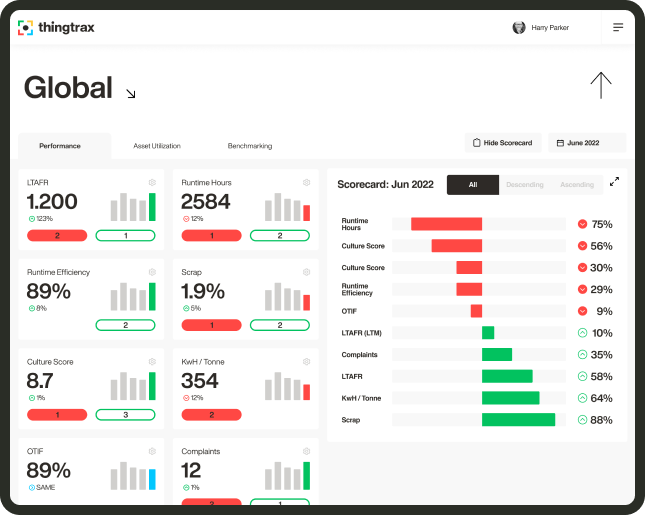

With drag-and-drop tools for planning and rescheduling, accurate plans can be laid out in advance. Your teams will benefit from advanced visibility of the production pipeline, with newfound agility to adjust and deliver on customer demands. Gain insight from detailed reports for downtime analysis, tool changes, shift benchmarking, factory benchmarking, as well as loss and waste. The Global Dashboard allows team members to identify production issues and drill down to a granular level based on real-time data. With shared data and reporting, teams have complete transparency on operational issues and can more quickly identify and resolve problems.

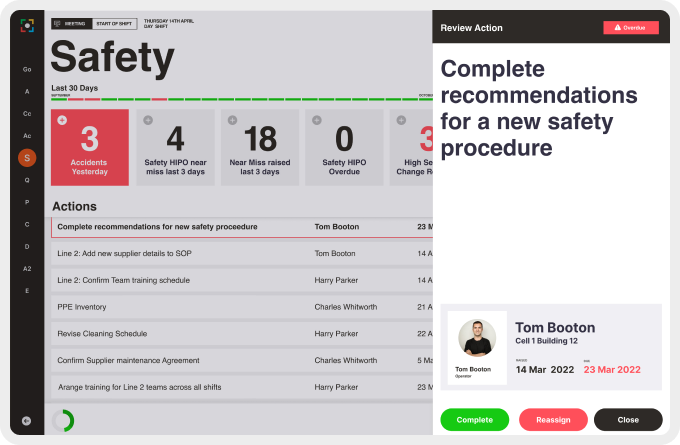

With additional software modules available for measuring Quality, monitoring Maintenance, and assessing Sustainability, our Productivity suite can help you achieve operational excellence.