Highlights from our discussion with beverage manufacturing innovator, Southern Champion

On February 7, 2024, Thingtrax partnered with Food Manufacture to host a live webinar, “Digital Transformation: Actionable Insights for Food and Beverage Manufacturers”. The session featured a presentation on industry megatrends from Thingtrax’s Allan Carney, as well as a fireside chat. The chat was moderated by Thingtrax’s Mark Bishop, with contributions from Allan as well as our special guest, Sammy Nassiri, VP of Engineering for beverage innovator Southern Champion. The themes of the discussion are included below, with actionable insights for food and beverage manufacturers.

It may have surprised some webinar attendees to hear that the biggest challenges with integrating smart manufacturing technology are not technical issues at all. Allan’s presentation highlighted how radio networks, IoT devices, and integration protocols have removed the traditional barriers of cost and complexity for small- to medium-sized manufacturers. But of course, drastic change is never easy, and our guests discussed some bigger challenges: gaining early momentum; shifting cultural mindsets; sustaining continuous improvement processes; and effectively moving to data-based decision-making.

This webinar is available on-demand,

Getting Started: A Clear Problem is A Glorious Opportunity

For manufacturers in the earliest stages of digital transformation, a common hurdle is having a clear plan and gaining buy-in from stakeholders. To build a shared vision of the opportunity, you should focus not on the impressive capabilities of today’s technology but on specific problems on your shop floor that can be improved.

Allan Carney: “Take it from first principles. As much as I’m an advocate of Industry 4.0, people shouldn’t embark on digitisation or any other project just because they think it’s the right thing to do. It should always be for a specific purpose. The best place to start is to focus on the actual problem you’re trying to solve, and then seek the technology which best fits your solution.”

Sammy Nassiri: “My advice would be to start with a brutally honest SWOT analysis, and really identify the weaknesses and opportunities that you’ve got, and then take a step forward.”

A rigorous focus on solving a specific manufacturing challenge can help your team align on a shared, practical vision of the potential for smart manufacturing technology in your organization. To explore how one Operations Manager built a bullet-proof business case for digital transformation, visit our infographic The ROI of Smart Manufacturing.

Implementation: Ensuring a Smooth Rollout

With the leadership team aligned on a solution, it’s time to implement. Again, our experts emphasised that any hardware or software issues can be solved with the right requirements and skills. A more critical factor is the importance of sound change management practices to ease the transition for teams.

Sammy Nassiri: “For a smooth transition, it’s best to introduce the concept early on. We were successful by gathering the team of end-users – the supervisors, line leads, and production managers – and discussing our challenges and what’s preventing us from being successful.

Then you can present this technology as a solution and make sure they understand how it can help us. That’s followed by training to show how the system works and how they can use the data and insights to achieve their goals and the organisational goals. It very quickly becomes sought-after.”

Allan Carney: “I always start by explaining the vision. I find if we get this piece nailed up front so people understand it, they tend to buy in sooner. My approach is just to be open and honest with the staff. Explain what you’re doing, explain why you’re doing it, and explain how it will impact them and the benefits it will bring them. And even if there are potential downsides, explain them too. It’s all about honesty and transparency, sharing the vision, and then celebrating the steps to get there.”

Allan offered some additional practices and tools that can help with a smooth rollout. The Thingtrax team recently launched an application to manage meetings and processes through the client implementation and onboarding process. For clients and the Thingtrax team, it tracks every required action and provides shared visibility.

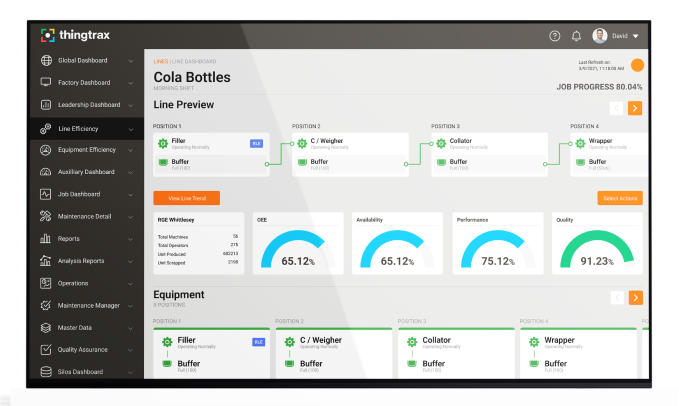

He also described how Thingtrax and Southern Champion collaborated on a customised operator application, using input from the Southern Champion team to make the interface simple for operators. “We collected a lot of feedback from the operators on the shop floor – what information do you need, how do you want it, where does it display? Once we released it, the feedback we received was ‘it’s just so simple.“

Cultural Barriers: Overcoming Resistance to Change

Digital transformation involves much more than introducing new technology – it requires an enterprise-wide evolution to a performance-based culture. From the CEO to the line workers, no one is exempt from change. New sources of visibility and data bring a sense of scrutiny that can make some team members feel defensive. Our panellists discussed the best ways to navigate this challenge.

Sammy Nassiri: “A smart factory is one that not only embraces new technology but also leverages it to improve performance. That means shifting to a more performance-based culture, and you have to start by creating the buy-in and helping the end user understand why the technology is necessary and how it’s going to help them achieve their goals. If you do that consistently, the culture will shift to a new performance-oriented culture with habits tailored to success.”

Allan Carney: “Within the first month or two, operators start warming to the system because they start to see the benefits it brings them on a day-to-day basis. When you speak to operators prior to digitisation, they’ll start complaining about machine breakdowns and say ‘Nobody listens to me – this has been happening for ages’. Digitisation takes the emotion out of it and gets everybody working off the same sheet. So, when operators are facing these repeat problems, they don’t feel like they’re arguing with everyone. It becomes a collaborative thing where people sit around a single version of the truth, a single data set, and see what the issues are.”

Allan also emphasised the importance of engaging employees through a real example of what not to do:

“I’ve seen a factory with a really detailed data capture system that no one had to interact with. It was completely autonomous. So, when I’d ask operators on the shop floor ‘What’s your performance like today?’ the standard answer is ‘I don’t know. The computer takes care of that.’ And that terrifies me because digitisation should be bringing humans and data closer together, not putting a block in between us.”

Maintaining Momentum: How to Sustain Continuous Improvement

Change can’t happen all at once. Post-launch, there are two important steps. Allan describes the importance of ensuring data accuracy, which can be a challenge when some team members have longstanding assumptions about productivity levels.

Allan Carney: “When we bring these systems in, we often find that what the planners believe happens on the shop floor doesn’t actually match the reality. So we tend to go through this process of data cleansing and ensuring that there’s accuracy of data. We work through the steps to ensure we’ve got accurate data, and we can then start using it.”

With data accuracy confirmed, Sammy emphasised the importance of ensuring that the right mindset and disciplines are in place to create a habitual focus on efficiency and optimisation.

Sammy Nassiri: “It’s a stair-step plan. Continuous Improvement is never-ending. You can never be perfect, but you can work towards it. You won’t have 100% performance tomorrow just because you now know where the problem is. It’s going to be a little bit more challenging than that. But it is manageable to get to a very respectable level of efficiency with bite-size chunks, and that’s how we approach it. We take it one step at a time, measure our success, and move on to the next challenge.”

Sammy Nassiri: “Before Thingtrax, monitoring was always part of our process but it was analog. We tracked our effectiveness using notes, dry-erase boards, and daily recaps. And that worked, but it worked up to the point that we could check and verify. Our demand has been increasing 50-60% every year. As we moved to a 24/7 production schedule, we knew that we needed to become more efficient.

Fast forward to today, we’re not using those dry-erase boards anymore. We’ve got systematic monitoring that’s watching 24/7. Every morning we’ve got this nice little daily newspaper and it’s graded our performance, and it doesn’t just spit out a bunch of numbers and data that you have to translate. It provides insight for you and tells us where the opportunity is. At the end of the day, information is the key to the decision-making process.

We take that information and simplify it. We’ll look at the top three contributors to downtime or reduced throughput and we’ll attack those that day. Some challenges may require more investigation or investment, and we can use that same data to rationalise any capital proposals. Having that insight has helped us make better decisions and it keeps us better informed of what’s going on on the floor.”

Allan Carney: “Data itself is meaningless unless you do something with it. People in leadership positions like Sammy tend to really look forward to that newspaper that we distribute every day, but there are several different ways we distribute insights to different people in a manner that’s suitable for them. For instance, we can send WhatsApp messages to an engineer when a tool change is about to come up so they immediately have that information when they need it to enable them to take action. We can use popup notifications, and we can also actually run meetings using our software. It’s about extracting insight to provide the right information to the right people at the right time.”

A sincere thanks to our participants for providing their unique insights into the challenges and opportunities of digital transformation, while sharing many practical insights from their experiences. We covered a lot in half an hour, following an insightful presentation on Industry Megatrends from Allan Carney. If you are exploring the role of smart manufacturing technology for your organisation, you can book a demo for a first-hand look at how Thingtrax is driving improved manufacturing performance for clients like Southern Champion.

Allan Carney

Director of Industry Solutions, Thingtrax

Allan joined Thingtrax in 2021, bringing with him a wealth of experience in continuous improvement and Lean Six Sigma practices. With over 16 years of professional experience, Allan has held Continuous Improvement Leadership roles with several companies, including LINPAC Packaging, Aimia Foods Ltd., and Nice-Pak International.

Sammy Nassiri

VP, Engineering, Southern Champion

Sammy joined Southern Champion in 2018. As VP of Engineering, he helps drive improved efficiency and productivity for the Texas-based beverage manufacturer. He has a degree in Biochemistry from the University of Texas at Austin.

Mark Bishop

VP, Marketing, Thingtrax

With 10 years of experience developing growth strategies in tech, Mark is passionate about innovation, creating best-in-class experiences, and building successful teams.