MAINTENANCE

Reduce downtime and maintenance costs with Thingtrax Maintenance. A proactive approach to factory maintenance for longer asset life.

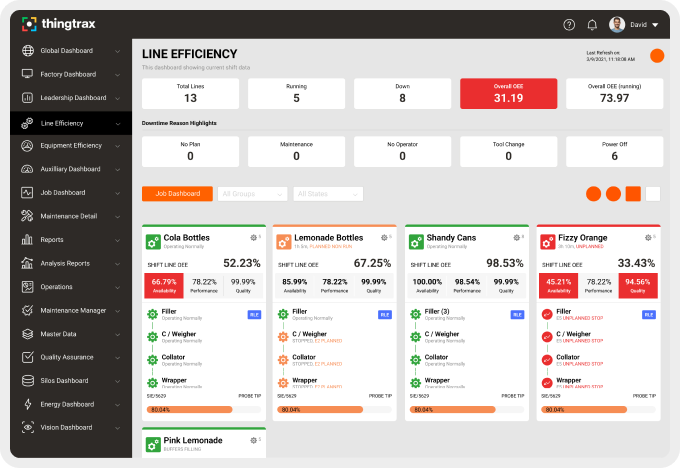

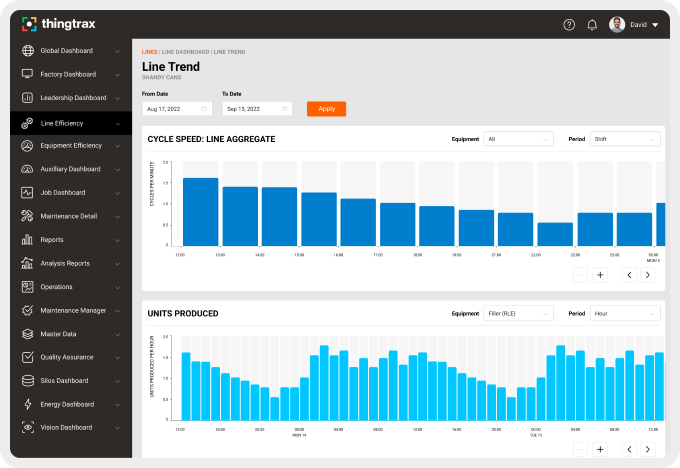

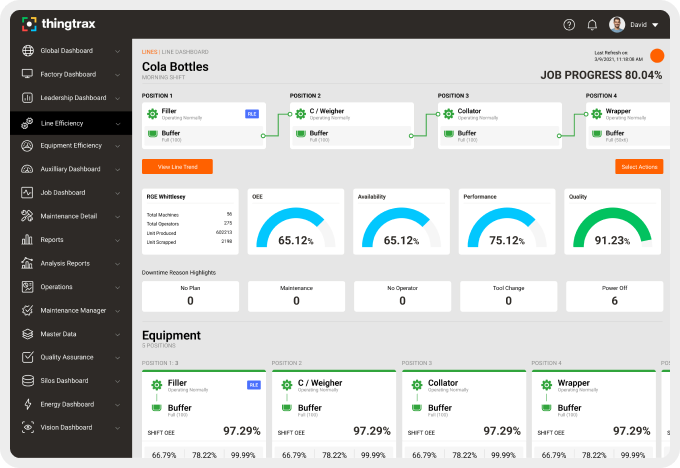

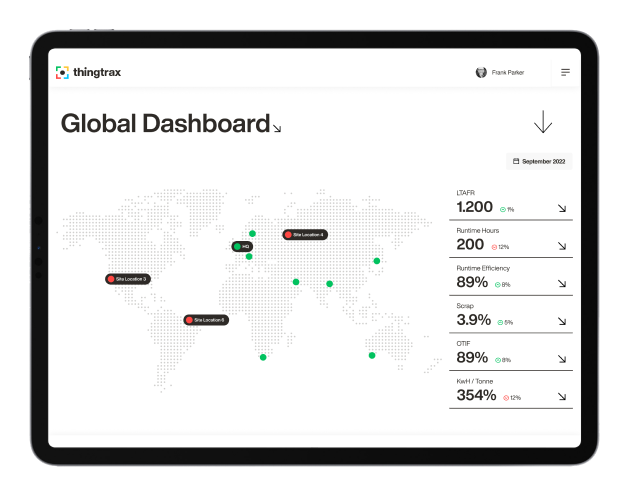

Overall Equipment Effectiveness (OEE) has become the prevailing standard for measuring the productivity of a manufacturing operation. It’s the go-to metric for Planners and Operators to assess efficiency. thingtrax Productivity embeds OEE into a real-time view, making it easy to understand where inefficiency exists. With the ability to pinpoint bottlenecks, the next step is to address key issues in order to reduce waste.

Recurring maintenance can be scheduled manually or automatically. Predefined triggers such as runtime or camera images from the factory floor can trigger a maintenance task. Thingtrax Maintenance allows maintenance professionals to plan proactively for the most effective schedule.

When thingtrax IoT sensors and cameras are installed on the factory floor, it opens up a new range of maintenance possibilities. Machine failure can be pre-empted using thresholds and triggers based on data relayed from the sensors in real-time. For example, excessive equipment vibration or temperature can trigger alerts to the Maintenance team, allowing them to take proactive action to avoid a critical failure.

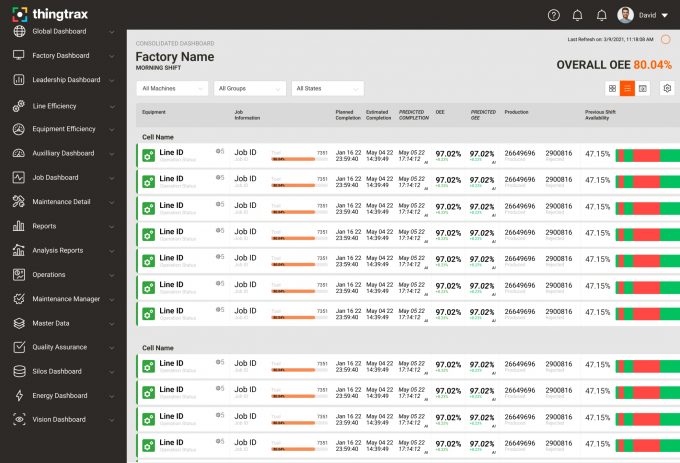

Predictive OEE involves using AI and machine learning models to forecast or predict future OEE based on historical data. These AI models are trained on past OEE data, allowing them to learn patterns, correlations, and factors between availability, quality and performance for a machine. This proactive approach allows manufacturers to take preventive actions to optimise equipment performance, minimise unplanned downtime, and enhance overall production efficiency, ultimately leading to more informed decision-making and improved operational effectiveness.

BENEFITS

COST

Maintenance scheduling prolongs asset life and reduces costs

OUTPUT

Reduced downtime caused by unscheduled repairs

AUTOMATED

Auto-schedule maintenance based on triggers such as runtime

RESPONSIVE

Preempt machine failure using sensor-based, real-time data

ADDITIONAL PRODUCTIVITY MODULES

SEEING IS BELIEVING

Book a free demo to understand how you can

- Gain instant visibility of performance and trends

- Seamlessly connect together every aspect of your production process, both digital and analogue

- Enable your workforce to take ownership for targets

During the call we’ll provide an overview on how Thingtrax’s customers use our platform to increase efficiency and reduce costs.