PERFORMANCE SOFTWARE FOR FOOD & BEVERAGE MANUFACTURING

Measuring manufacturing productivity can be particularly challenging in the food and beverage industry. Complex multi-step, multi-process, multi-machine production lines, often running 24/7, require an innovative approach to data collection. The Thingtrax product suite is designed to address these complex challenges.

Our proprietary sensors and cameras can harvest production data from every machine in a food and beverage production line. Manual assembly is captured and measured using AI-enabled camera vision.

The end result is real-time data on every aspect of food and beverage production, delivered in an intuitive interface with distinct role-based views for executives, managers, and line workers.

With a shared holistic view of every stage of the production line, teams at all levels of the organisation can take action to improve productivity and reduce waste.

Benefits for Food & Beverage Manufacturers

Integrated

Measure complex, multi-stage production lines, including manual activity

Real-time

Activate immediate alerts for quality or production efficiency issues

Compliant

Automate monitoring of safety standards and product quality

Shared

Generate one consistent view of productivity across all teams

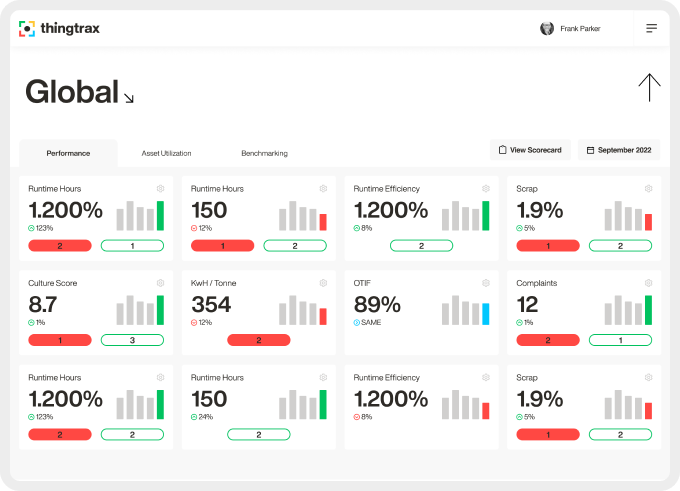

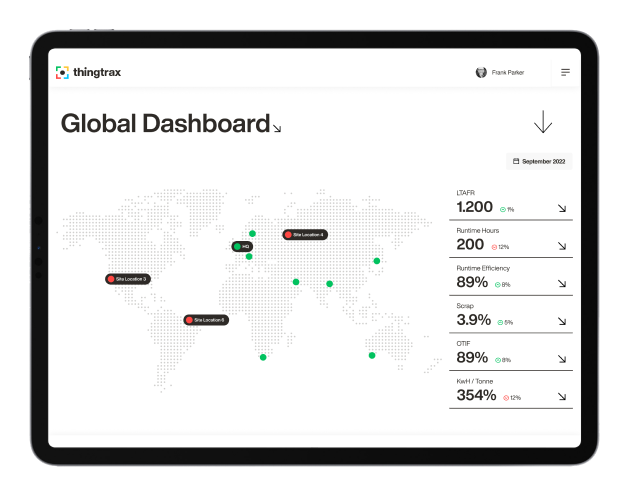

Thingtrax Leadership Dashboard allows leaders to rapidly assess operational efficiency and spot bottlenecks. A consistent method of harvesting data means apples are compared to apples, across countries, factories, teams, products and machines. A CEO can easily view production trends, or compare against internal standards or external benchmarks for the food and beverage industry.

With seamless integration with other Thingtrax modules, additional reports on Productivity, Quality, Maintenance, and Sustainability can provide a complete view of the organisation’s progress against key goals

Thingtrax Daily Management empowers your organisation to develop a high-performance culture at all levels. Increase accountability for teams and individuals with goal-based KPI reporting, and tools and templates to support continuous improvement processes.

Teams conduct daily huddles centred around a data-rich visual board showing key productivity measures and targets. Tasks are assigned to specific team members and tracked through to completion. A comprehensive set of processes and workflows ensures all teams are equipped with best practice tools and methods for problem solving.

Thingtrax uses proprietary equipment and unique methods to measure all aspects of productivity in food and beverage manufacturing. For both modern and legacy machines, sensors can capture machine activity regardless of run signal. All devices operate through a mesh network of radio signals, linked to a single gateway that transmits to the cloud. This means installation is quick and easy, using existing infrastructure.

Inefficiency in manual processes can typically be very difficult for food and beverage manufacturers to measure. Thingtrax captures and relays quantifiable data from human processes through camera vision and AI processing. Images captured in real-time are measured not only for output but also quality and accuracy.

In food and beverage factories, we can train cameras to detect when an item is misshapen, positioned incorrectly, or simply missed. Camera vision can also detect hygiene compliance issues, such as a worker operating without a snood or hairnet. With a detailed view of the productivity of both machines and manual workers, leaders have a full picture of where waste occurs and where hygiene compliance is at risk.

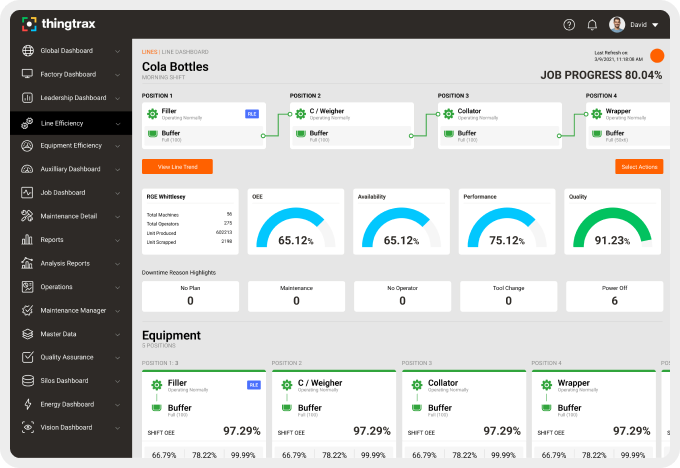

Thingtrax Productivity aggregates every data point in a food and beverage production line within an intuitive user interface. This holistic line view provides real-time line OEE calculation. It allows managers to quickly assess productivity and spot bottlenecks within a complex production line.

Line view uses the rate limit of individual machines to calculate impacts across an entire line. If a machine should fail, Thingtrax Productivity uses its rate limit to determine how much product others can accumulate with no productivity loss once the machine is restored at a higher rate. These complex calculations are delivered in seconds, providing managers with immediate data to support decision-making when every second counts.

ENGAGING THE ENTIRE WORKFORCE

INSIGHT

Turn your factory floor into a rich data network with IoT sensors

DATA

Receive real-time, quantitative data for manual processes

SATISFACTION

Put intuitive tools in the hands of machine operators

ENGAGEMENT

Build a visual workplace where teams can easily assess productivity

SEEING IS BELIEVING

Book a free demo to understand how you can

- Gain instant visibility of performance and trends

- Seamlessly connect together every aspect of your production process, both digital and analogue

- Enable your workforce to take ownership for targets

During the call we’ll provide an overview on how Thingtrax’s customers use our platform to increase efficiency and reduce costs.