THINGTRAX VISION

Empowering Efficiency: Thingtrax

Vision for Manufacturing Excellence

VISION AI

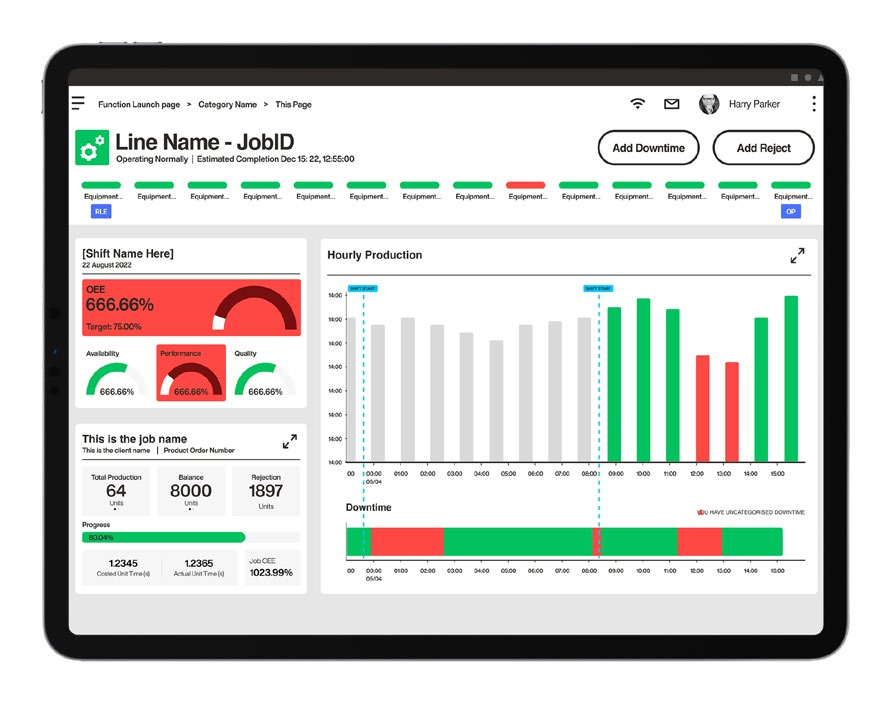

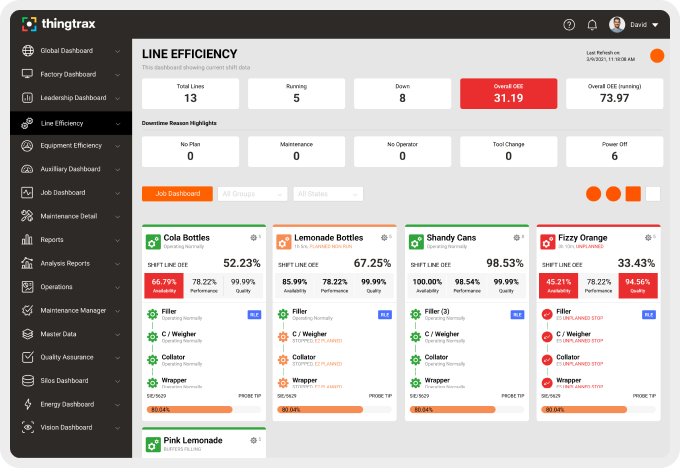

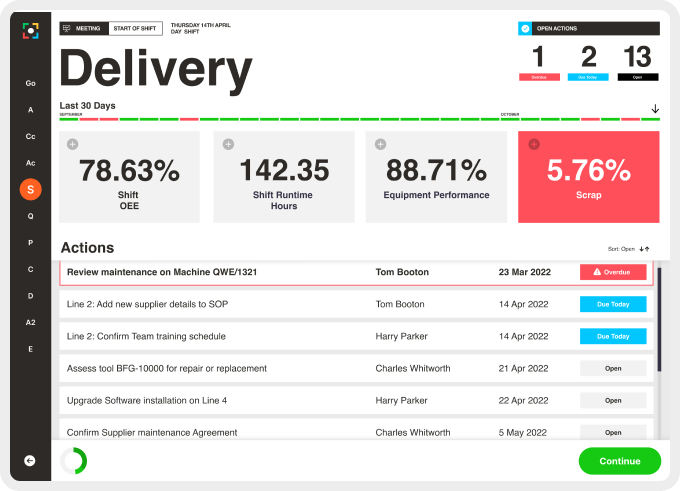

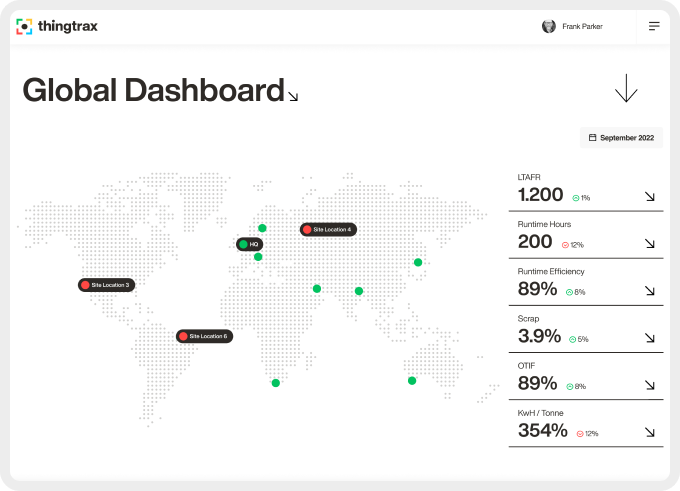

Thingtrax Vision, utilising cameras in manufacturing offers several advantages, including real-time monitoring for prompt issue identification, automated data collection for accurate OEE calculations, quality control and defect detection. It is fast to deploy and avoids costly and slow integrations with machines, helping to quickly enable manufacturers to enhance production efficiency, making them more competitive.

Product Defects

Vision technology accurately identifies food defects, ensuring adherence to safety standards and enhancing product quality. Real-time analysis minimizes risks, safeguarding consumer satisfaction and brand reputation, critical in the food industry for maintaining competitiveness and trust.

Label Validation

For label validation, our vision technology ensures accuracy and compliance with regulatory standards. Real-time analysis detects discrepancies, mitigating risks and ensuring label integrity. This capability is essential for maintaining regulatory compliance and consumer trust in the market.

Health and Safety

Deployed throughout the factory floor, our cameras are equipped with advanced detection and recognition capabilities. This

allows the identifcation and verification of operators who are not adhering to essential safety protocols. Notifications are relayed in real-time to the portal, ensuring immediate visibility and automatic reporting of compliance status.

Pallet Integrity

Ensure pallet integrity with accurate identification of flaws or irregularities, along with real-time analysis to minimise risks, ensuring safe handling and transportation of goods. This proactive approach enhances operational efficiency, reduces damages, and upholds supply chain reliability.

HOW IT WORKS

Thingtrax Vision is quick to deploy and requires no integration with factory machines. Any camera with a RTSP support can be used to record data. Our team of experts work with you to configure the AI model , which is trained in 7 days. Once live all of data and reports are displayed in a web-based dashboard.

Implementing Thingtrax Vision in your factory brings a range of valuable benefits. By harnessing advanced camera technology strategically placed within the production process, real-time monitoring becomes possible, ensuring prompt identification of any potential issues. The system’s automated data collection provides accurate measurements of crucial metrics, ensuring that only top-quality products make it to the market, minimising waste and maximising customer satisfaction. The system’s fast deployment and seamless integration eliminate the need for costly and time-consuming machine integrations, enabling swift adoption and immediate impact on production efficiency.