PERFORMANCE SOFTWARE FOR PLASTICS MANUFACTURING

Thingtrax removes barriers to real-time data for plastics manufacturers with proprietary, machine agnostic sensors and AI-enabled vision cameras that capture all production activity.

Measure and analyse all aspects of plastics manufacturing, including manual processes, continuous flow extractors, and multi-part injection moulders.

With a shared view of manufacturing productivity, teams at all levels of the organisation can take action to improve efficiency and reduce waste.

Benefits for Plastics Manufacturers

Visible

Generate real-time line OEE reporting for leaders and teams

Versatile

Measure continuous flow extrusion, or moulders producing multiple parts

Immediate

Identify and quickly respond to quality control issues

Complete

A holistic view of productivity that includes manual activities

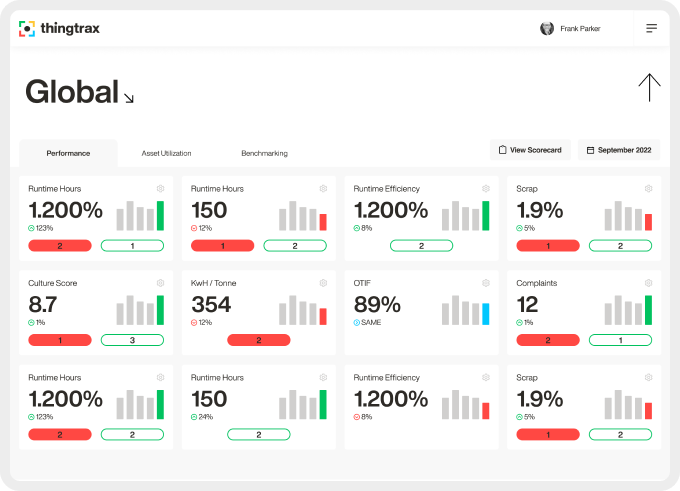

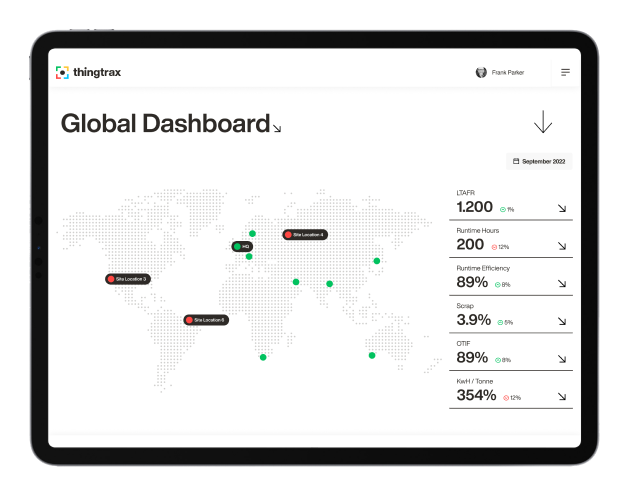

Thingtrax Leadership Dashboard allows leaders to rapidly assess operational efficiency and spot bottlenecks. A consistent method of harvesting data means that teams are working with one single source of truth across locations, facilities, teams, products and machines. A CEO can easily view production trends, or compare against internal or external benchmarks for the plastics industry.

With seamless integration with other Thingtrax modules, additional reports on Productivity, Maintenance, Quality, and Sustainability can provide a complete view of the organisation’s progress against key go

Thingtrax Daily Management empowers your organisation to develop a high-performance culture at all levels. Increase accountability for teams and individuals with goal-based KPI reporting, and tools and templates to support continuous improvement processes.

Teams conduct daily huddles centred around a data-rich visual board showing key productivity measures and targets. Tasks are assigned to specific team members and tracked through to completion. A comprehensive set of processes and workflows ensures all teams are equipped with best practice tools and methods for problem solving

Thingtrax uses proprietary equipment and unique methods to measure all aspects of productivity in a plastics factory.

Sensors capture electronic pulses corresponding to cycle times of ejection moulders and extrusion machines. For continuous flow extrusion, we offer a proprietary device that calculates analog output and run-speed to measure production.

All devices operate through a mesh network of radio signals, linked to a single gateway that transmits to the cloud. This means installation is quick and easy, using existing infrastructure with no additional wiring required.

In a plastics factory, the bulk of the work (and productivity losses) occurs outside of the machinery.

Thingtrax captures and relays quantifiable data from human processes through camera vision and AI processing.

Images captured in real-time are measured not only for output but also quality and accuracy. In plastics, we can train cameras to detect when an item is misshapen, positioned incorrectly, or simply missed. With a detailed view of the productivity of both machines and manual workers, leaders have a full picture of where waste occurs.

Thingtrax Maintenance allows teams to proactively assess and plan a smarter machine maintenance cycle.

Many plastics manufacturers, often using legacy equipment with analog signals, service machines based on a fixed schedule. But if one moulder has been continuously running 24/7 and another has been run every Sunday, servicing the highly-used machine is most urgent.

Deriving run-time data from Thingtrax sensors, in addition to the trigger-based scheduling features of Thingtrax Maintenance, can reduce maintenance costs and proactively prevent critical failure.

ENGAGING THE ENTIRE WORKFORCE

INSIGHT

Turn your factory floor into a rich data network with IoT sensors

DATA

Receive real-time, quantitative data for manual processes

SATISFACTION

Put intuitive tools in the hands of machine operators

ENGAGEMENT

Build a visual workplace where teams can easily assess productivity

SEEING IS BELIEVING

Book a free demo to understand how you can

- Gain instant visibility of performance and trends

- Seamlessly connect together every aspect of your production process, both digital and analogue

- Enable your workforce to take ownership for targets

During the call we’ll provide an overview on how Thingtrax’s customers use our platform to increase efficiency and reduce costs.