Learn from manufacturing innovators

DATA CAPTURE & DISPLAY

Our easy-to-install sensors capture digital or analog electrical signals from your equipment. Factors such as vibration, temperature and workload are then shared in real-time with our software suite.

Digital cameras provide a view of floor locations where workers are an important part of the production process. Images are interpreted using computer vision and AI, resulting in real-time oversight of human processes.

IoT sensors can transform manufacturing equipment into rich data sources that feed a network of productivity information. Set-up is simple, with no infrastructure changes required. Our devices, which operate on a radio network, can capture either digital or analog electrical signals from machines. With data feeding in from all activity on the factory floor, you have insight into machine performance and process control parameters, with minimal installation costs. The sensors are capable of capturing multiple types of readings such as vibration, temperature and workload.

Digital cameras facilitate data capture for manual tasks. The images are processed using a combination of computer vision and AI logic. This enables data to be captured where no electrical signals are present, and allows for real-time oversight of human processes that impact productivity. It provides quantitative, real-time data for processes that previously could only be observed by walking the factory floor.

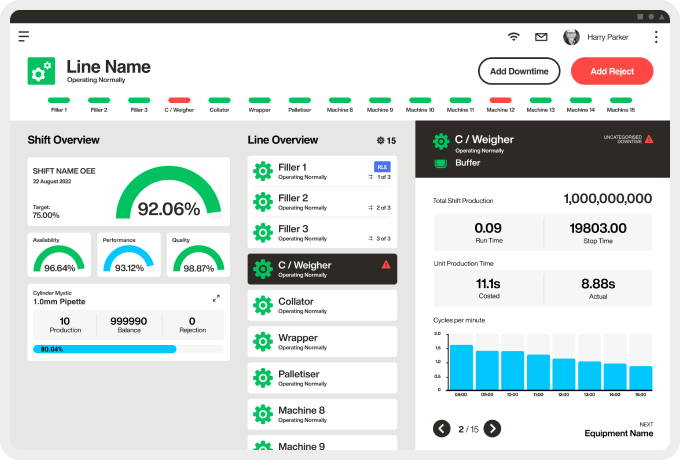

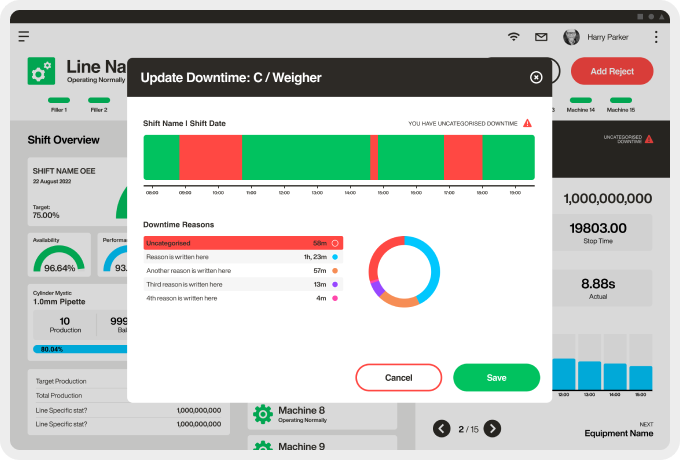

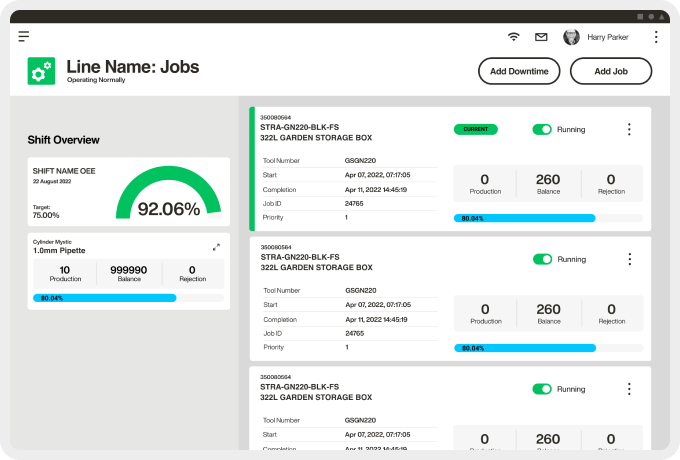

Thingtrax provides a tablet-based operator app that provides machine operators with all the information required to effectively run their equipment. It has a simple and clear display of equipment diagnostics, and allows operators to easily input new data, such as scrap, or manual production.

User-centric simplicity is key – the app is easy to adopt as it provides only the info required to make decisions within the operator’s sphere of influence. This reduces training time, enables in-the-moment capture of data from the shop floor, and increases operator accountability.

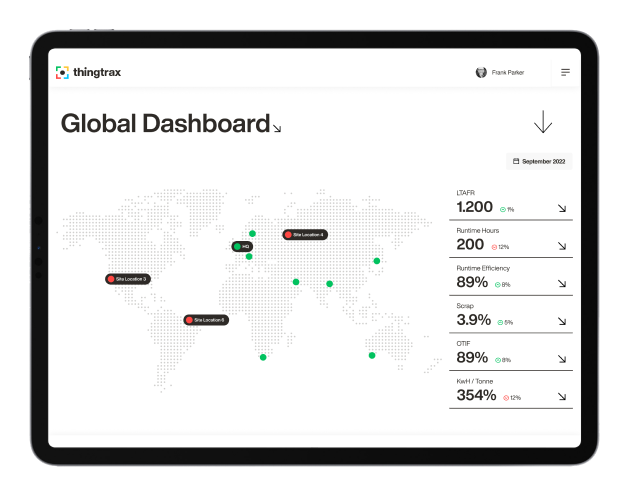

Teams are more motivated when they have a shared visual view of their goals and progress. We promote visual workplaces by installing large-screen displays on the factory floor. Workers who don’t normally access screens or reports can view the team’s productivity and key performance metrics at a glance. This helps build a high-performing culture and increases response time to nonstandard performance.

BENEFITS

INSIGHT

Turn your factory floor into a rich data network with IoT sensors

DATA

Receive real-time, quantitative data for manual processes

SATISFACTION

Put intuitive tools in the hands of machine operators

ENGAGEMENT

Build a visual workplace where teams can easily assess productivity

SEEING IS BELIEVING

Book a free demo to understand how you can

- Gain instant visibility of performance and trends

- Seamlessly connect together every aspect of your production process, both digital and analogue

- Enable your workforce to take ownership for targets

During the call we’ll provide an overview on how Thingtrax’s customers use our platform to increase efficiency and reduce costs.