In this instalment of our Manufacturing Performance Blog Series, we highlight the innovative data capture methods driving new levels of manufacturing productivity.

In today’s competitive manufacturing landscape, efficient and versatile data capture is vital. The industry is evolving rapidly; a survey from Deloitte’s 2024 Manufacturing Industry Outlook reveals that “nearly half of manufacturers are already harnessing the power of IoT sensors, devices, and systems.” Thingtrax empowers these advancements with an innovative and comprehensive data capture system designed to meet diverse manufacturing needs.

Advanced IoT Data Capture

Thingtrax’s IoT data capture system sets a new benchmark for adaptability and accuracy. Our proprietary devices capture both digital and analog signals, making them versatile for various types of machinery and sensors.

This capability extends to communicating via the RS485 standard, allowing seamless integration with a range of sensors and transducers. Whether it’s monitoring machine performance, silo levels, temperature, humidity, flow, pressure, or other critical parameters, our devices ensure comprehensive and reliable data capture.

Energy Monitoring – A Crucial Innovation

Rising energy costs and the drive toward sustainable manufacturing make energy efficiency more critical than ever. Thingtrax has responded to this challenge by incorporating energy monitoring sensors into our IoT devices. Our current transformers (CTs) facilitate easy and non-intrusive installation, enabling precise tracking of energy usage. This capability equips manufacturing leaders with insights into energy consumption patterns that facilitate informed decisions for energy management.

Vision Data Capture – Leveraging AI and Edge Computing

Our AI-driven vision system, integrated within the IoT framework, represents a leap in manufacturing data capture. It enables the tracking of processes traditionally monitored by human observation, such as safety compliance checks, quality inspections, and hygiene standards – crucial in industries with stringent safety requirements like food and beverage. Our vision system converts traditional productivity blind spots into measured processes with benchmarks, creating a new foundation for analysis and performance improvements.

Seamless Integration with Existing Systems

Thingtrax’s technology is designed to work in tandem with existing enterprise systems, including ERPs. By adhering to the latest protocols and best practices, our devices ensure a unified approach to data management, enhancing the efficiency and connectivity of manufacturing operations. The ultimate benefit is seamless data integration for our manufacturing clients.

The Thingtrax Mesh Network – Simplifying Scalability

A key advantage of our system is the Thingtrax Mesh Network. This network simplifies the process of adding new sensors by eliminating the need for costly and extensive infrastructure changes. Requiring no Wi-Fi or ethernet cabling, the network’s flexible design facilitates the simple integration of new devices, significantly cutting down the time and expense associated with expanding data capture capabilities.

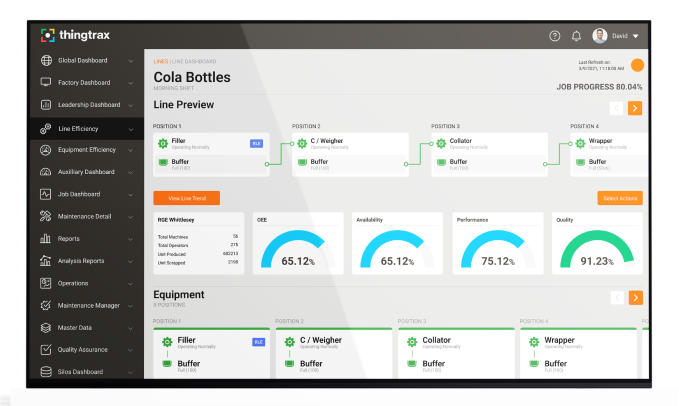

Thingtrax stands out in the field of manufacturing data capture with its extensive range of capabilities. From advanced IoT data collection, including energy and vision data capture, to its seamless integration with existing systems and the easily scalable Thingtrax Mesh Network, Thingtrax is an indispensable asset in modern manufacturing. Stay tuned for the next post in our Manufacturing Performance Blog Series, where we explore how Thingtrax transforms comprehensive data into actionable insights for operational efficiency and innovation.