In a rapidly evolving and competitive environment, innovation is essential. In this instalment of our Manufacturing Performance blog Series we introduce Thingtrax, a manufacturing performance platform that goes beyond a conventional Manufacturing Execution System (MES). Whether you’re a shop floor manager, a data analyst, or a c-suite executive, Thingtrax delivers true insight within your sphere of influence to empower effective decision making. We’ll highlight how Thingtrax is redefining data capture and operational efficiency in the manufacturing industry, but first, let’s go back to the beginning…

The Origin of Thingtrax

Our journey began within a family-owned factory, where the challenges of modern manufacturing were more than just theoretical concepts for Aman Gupta. Working together with longtime friend and colleague, Imran Shafqat, a seasoned software engineer, their pragmatic and collaborative approach laid the foundation for the manufacturing performance platform that exists today. Our Founders continue to guide an ever expanding and high-performing team to continually evolve and adapt Thingtrax to meet the challenges of the manufacturing world.

Our Focus on WCM and Lean Principles

At the heart of Thingtrax is a philosophy deeply ingrained in World-Class Manufacturing (WCM) and Lean principles. Our platform is not limited to data capture; we use this data to generate insights and integrate these seamlessly within the fabric of existing WCM practices. Thingtrax aligns perfectly with methodologies like Lean Daily Management, ensuring that the insights and efficiencies work together with established best practices across your manufacturing estate. This integration fosters a culture of continuous improvement, empowering teams to make data-driven decisions, maximising productivity and profitability.

A Cross-Functional Team Customised for Manufacturing

The foundation of first principle thinking to solve manufacturing challenges is reflected in our team of cross-functional professionals with extensive manufacturing experience. Our combination of theoretical knowledge and practical expertise ensures that Thingtrax is directly applicable for our users at every tier of the organisation, providing the right information at the right time for optimal decision making. This practical orientation allows us to offer solutions that are intimately aligned with the day-to-day complexities of manufacturing operations.

The Thingtrax Manufacturing Platform

Equipped to cater to every aspect of manufacturing operations, Thingtrax quickly and seamlessly integrates with existing enterprise systems to ingest data, and comes with a wide range of standard functionality:

- Operator App: The Operator App intuitively presents shop floor operators with real-time production information to facilitate easy access and input of information.

- Maintenance Module: A versatile tool for managing maintenance schedules, tracking equipment health, and reducing downtime. This module allows maintenance tickets to be raised and tracked in several ways: manually, on a schedule, based on machine runtime, or machine or tool cycles.

- Quality Assurance (QA) Module: Our QA module facilitates quality control processes and ensures compliance with manufacturing standards. It enables tracking of complaints along with a team-based Root Cause Problem Solving framework.

- Problem Solving Tools: Thingtrax offers integrated functionalities for effective operational challenge resolution, including an 8D Root Cause Problem Solving framework. Our data visualisation tool enables custom chart and table generation on over 125 metrics, sliced by dozens of parameters.

- Energy Monitoring: Using our own sensors or integrating with your existing equipment, Thingtrax is designed for simple, quick, and non-intrusive installation, allowing you to effectively monitor energy usage and take the necessary action to optimize your consumption.

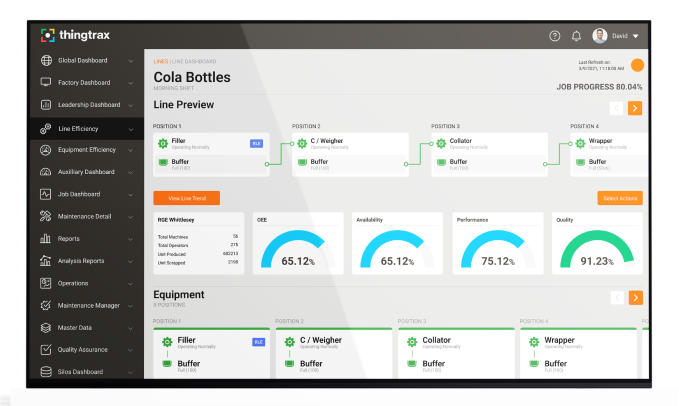

- Leadership Dashboard: A customisable, interactive dashboard for senior leadership to define, monitor and align objectives, cascading them to every level of the organisation to align all team members to deliver their best within their sphere of influence.

- Line Efficiency Tracking: View real-time production information for your entire line or any individual machine within it. Empower your operators to focus on issues affecting process output and provide industrial engineers with data for Line Balancing Optimisation.

- Vision System: Our fully customizable AI-driven camera systems deliver new insights for precision and compliance monitoring. Quick and simple to install, the Thingtrax Vision system can be adapted to capture almost any process in a factory. Use cases include label validation, in-line quality monitoring, PPE and hygiene compliance, and manual processes such as assembly and counting production or rejection, especially where no electrical signal is available.

- Management App: Taking the best of Lean Daily Management practices and evolving them for the digital environment, this comprehensive app allows managers to oversee operations and make informed decisions by creating a daily system of accountability. This system increases employees’ sense of ownership, while supporting intuitive tracking and reporting on actions.

- Comprehensive Reporting Suite: Our suite includes analysis tools, standardised reports, and automated, customisable reports that can be scheduled and sent via email.

- Alert System: Trigger alerts for events like machine downtime, enabling prompt responses and effective action. Messages can be delivered in-app, via email or even configured as signals to trigger established systems within your manufacturing estate.

- Condition and Environmental Monitoring: Monitor silo levels, temperature, humidity, flow, pressure, sound, vibration and more.

- Performance Monitoring: Role-specific dashboards enable each stakeholder, from shop floor workers to C-suite executives, to focus on their sphere of influence and make insight-driven decisions for maximum effectiveness.

- Job Planning & Scheduling: Integrate with ERP systems for efficient job planning, with options for CSV upload or direct scheduling using Thingtrax’s built-in functionality. Use real-time visualisation to easily monitor conformance to plan.

Thingtrax is more than a technological tool; it’s a strategic ally in your manufacturing journey, designed to empower decision-making across your entire team. Our platform is designed to adapt to the ever-changing challenges within the manufacturing environment and is continuously evolving to match our customers’ needs.

In upcoming posts, we will explore how Thingtrax stands apart in digitising manufacturing operations, offering unparalleled insights and operational efficiencies. Our commitment is to not just provide data but to transform it into actionable insights that align with and enhance your existing WCM and Lean practices, to maximise your productivity.