PRODUCTIVITY

Measure the pulse of your manufacturing operation. OEE is displayed in real-time, making it easy to understand where inefficiency exists. With drag-and-drop tools for planning and rescheduling, accurate plans can be laid out in advance. Gain insight from detailed reports for downtime analysis, tool changes, shift benchmarking, factory benchmarking, as well as loss and waste.

Overall Equipment Effectiveness (OEE) has become the prevailing standard for measuring the productivity of a manufacturing operation. It’s the go-to metric for Planners and Operators to assess efficiency. thingtrax Productivity embeds OEE into a real-time view, making it easy to understand where inefficiency exists. With the ability to pinpoint bottlenecks, the next step is to address key issues in order to reduce waste.

Is your production planning done on a just-in-time basis (i.e. last minute)? Move from reactive to proactive planning with thingtrax Productivity. With drag-and-drop tools for planning and rescheduling, accurate plans can be laid out in advance. Your teams will benefit from advanced visibility of the production pipeline, with newfound agility to adjust and deliver on customer demands. Business benefits include reduced administrative overhead, more revenue per machine, more customer orders On Time In Full (OTIF), and reduced inventory carrying costs.

Measuring productivity on a per-machine basis leaves significant knowledge gaps in a multi-stage production line. thingtrax Productivity incorporates a line view, with an OEE measure for the entire production line. Line view brings to the surface the spots where efficiency loss occurs in a production line. More importantly, it can identify the top losses impacting overall production.

The thingtrax hardware suite includes AI-guided camera technology that monitors manual assembly activities to prod uce real-time, quantitative data. Within thingtrax Productivity, this data can produce several benefits, such as: identifying compliance and operating issues, optimising cycle and Takt times, improving product quality, and reducing rework, recalls, and waste. It has additional value in pinpointing areas for process improvement, and improving employee training.

The thingtrax Productivity suite provides comprehensive reporting capabilities. Day-to-day, operators find it useful for rapid problem identification and resolution. More broadly, it empowers leaders engaged in process improvement, efficiency analysis, and business planning. Designed specifically for manufacturing companies, the Productivity suite features reports for downtime analysis, tool changes, shift benchmarking, factory benchmarking, as well as loss and waste.

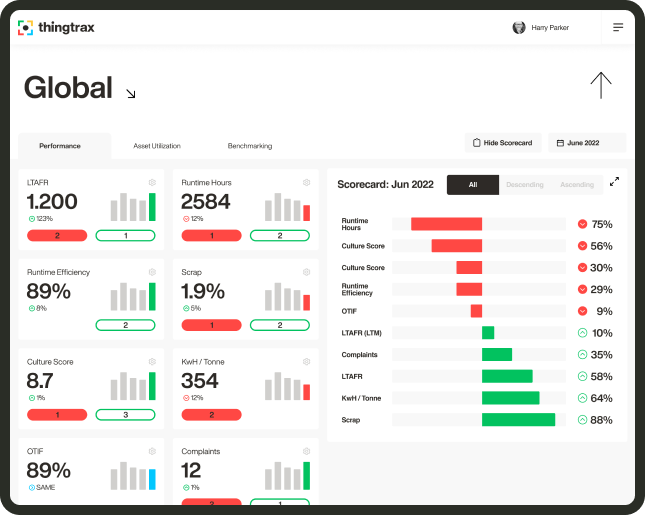

The Global Dashboard breaks down operational silos and exposes valuable multi-site data. Working groups all share the same visibility, and can compare against internal and external benchmarks. It allows team members to identify production issues and drill down to a granular level based on real-time data. With shared data and reporting, teams have complete transparency on operational issues and can more quickly identify and resolve problems.

BENEFITS

IMMEDIATE

Real-time OEE reporting shows operating efficiency at a glance

PROACTIVE

Move from reactive planning to proactive scheduling

EFFICIENT

Zoom out or drill down on line activity to spot bottlenecks in real-time

INSIGHTFUL

Comprehensive reports with internal and external benchmarking

ADDITIONAL MODULES

PRODUCTIVITY MODULE GUIDE

Measure the pulse of your manufacturing operation in real-time. Quickly and easily understand where inefficiency exists.

Discover how to optimise your operations and increase efficiency with our comprehensive guide, featuring in-depth reports on downtime analysis, tool changes, shift benchmarking, factory benchmarking, and more.

Download your copy today

SEEING IS BELIEVING

Book a free demo to understand how you can

- Gain instant visibility of performance and trends

- Seamlessly connect together every aspect of your production process, both digital and analogue

- Enable your workforce to take ownership for targets

During the call we’ll provide an overview on how Thingtrax’s customers use our platform to increase efficiency and reduce costs.