Highlights from the Smart Factory Expo, 2023

Juergen Maier, former CEO of Siemens UK and former Chairman of Made Smarter, delivered a keynote focusing on the optimism and resilience of UK manufacturers:

“I feel it’s a period where we’ve come out of being in permanent crisis – from Covid, to Brexit, to energy costs. And, my goodness, our manufacturing sector has become resilient. Let’s use that grit and resilience and we can grow into new, more sustainable growth momentum for our great manufacturing sector.”

Manufacturing output is expected to fall by 3.2% this year, after a 4.4% decline in 2022. Faced with rising raw material prices, increasing borrowing costs, and shifting consumer demand, optimism can be hard to find.

At Thingtrax, our view is that it’s more important than ever for manufacturers to find new gains by improving what they can control: operational efficiency and waste reduction.

Data is Critical for the Path Forward

Steve Penver, the Group Head of Digital Integration at Babcock International, emphasised the importance of data and analytics in moving the manufacturing industry forward.

“Data and digital is … maturing at a really fast pace. IoT, big data platforms, and the use of analytics, allows us to collect more data around our assets, analyse it, and put it into the appropriate context. It enables us to model our business so we can optimise our services and proposition.”

The challenge to realising Steve Penver’s vision is not technology constraints – at Thingtrax, we’ve pioneered creative ways of measuring every aspect of manufacturing productivity, including analog machines and manual activity – it’s to gain more awareness and momentum for the industry’s shift toward data-driven operations.

Hewlett Packard’s Global Data Maturity Study found that just 28% of manufacturers see data and analytics as key drivers of their organisation’s value chain.

Digitisation Can Drive Sustainability Improvements

Stacy Dyer, Deloitte’s Product Development Lead, discussed how digitisation can help manufacturers meet sustainability objectives.

Her presentation covered the full life-cycle, from product design and material selection, through to end-of-life recycling, to address one central question:

“How can you make sure that you’re sustainably manufacturing and that you get the best from your facility?”

The manufacturing sector produces one-fifth of global carbon emissions, and consumes 54% of the world’s energy sources.

Of all the issues facing the manufacturing industry, climate change may be the most critical challenge of our lifetime. Establishing a data-driven baseline is the first step.

Many clients use our Sustainability module to track their carbon emissions and energy consumption.

Thingtrax: A Manufacturing Performance Platform

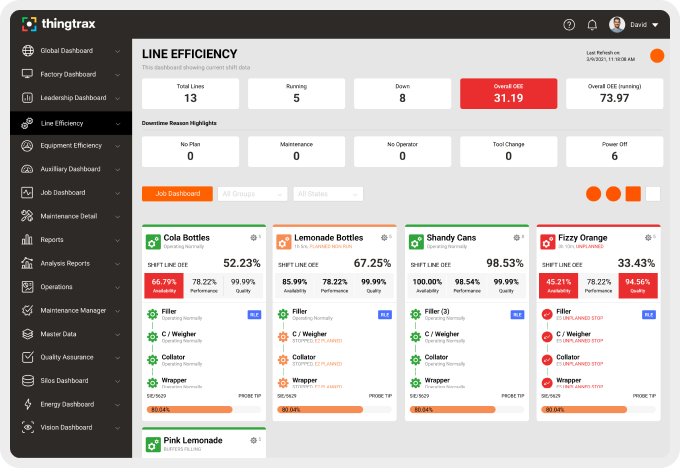

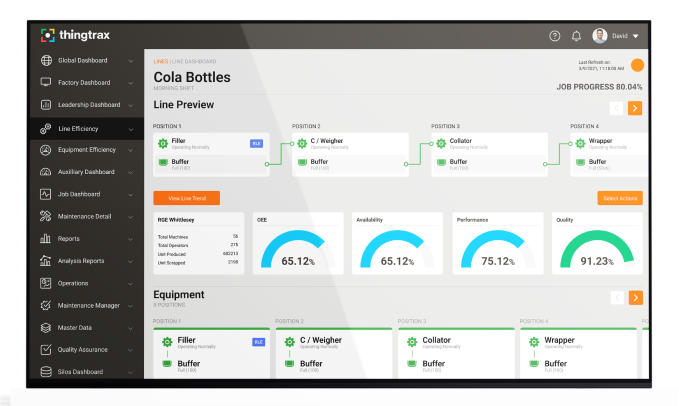

Thingtrax offers a complete solution for manufacturing leaders to improve operational excellence.

Capture data insights from all stages of production, digitise team processes for all functions, set performance objectives and targets, and engage employees to develop a high-performance culture.

The Thingtrax suite includes multiple, integrated modules:

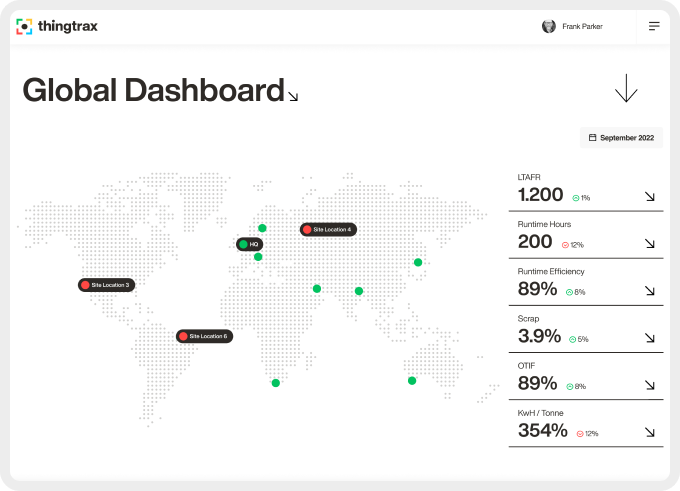

CEO Dashboard

A control panel for CEOs that provides real-time visibility of the organisation’s progress against key metrics such as OEE, quality, and safety.

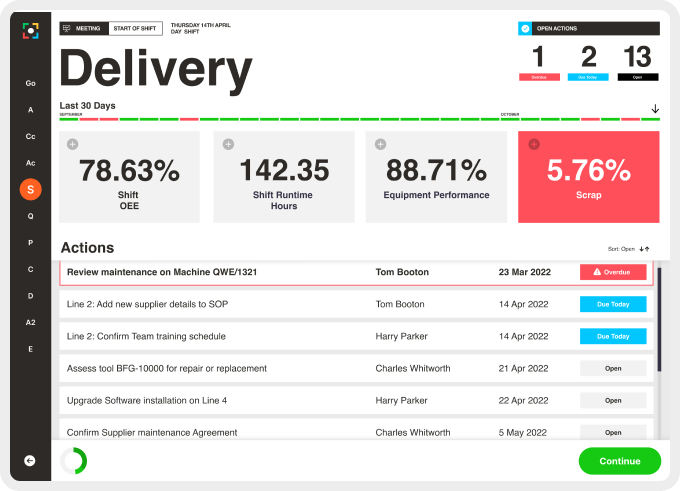

Daily Management

Enable Lean Six Sigma best practices for standardised daily meetings, shared goals and performance data, task tracking, and problem solving.