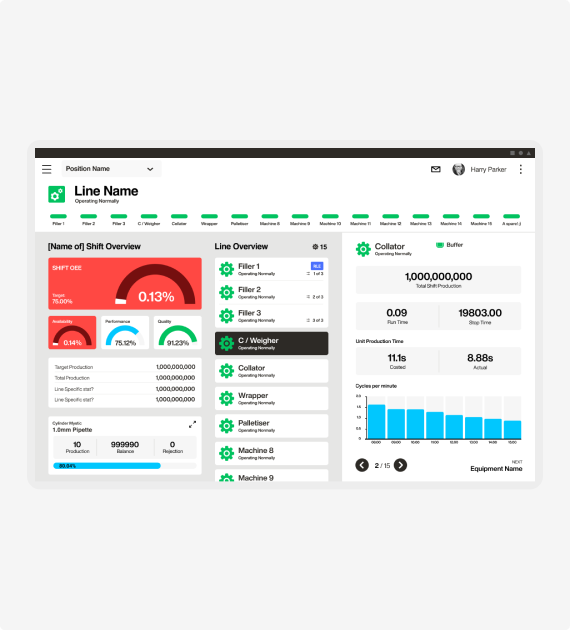

SET PERFORMANCE OBJECTIVES

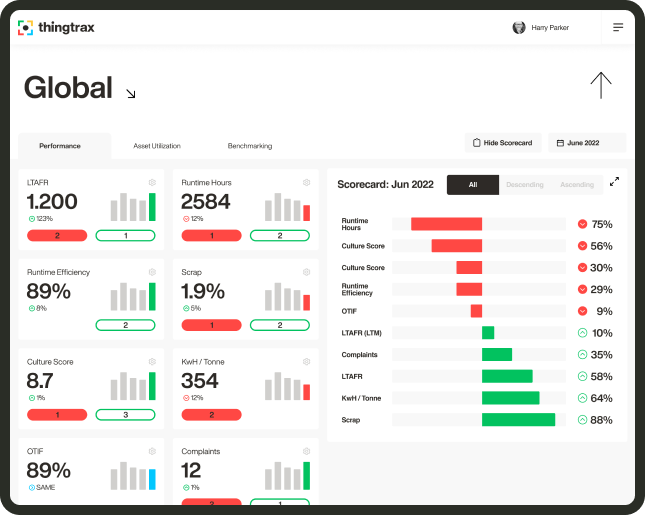

Set your manufacturing targets at the very top of your organisation. Allow your workforce to take responsibility and set their own targets to achieve the company goals. Vitally, this aligns your entire operation and gives each individual ownership within their sphere of influence.