Just like you, the Thingtrax team is constantly looking for ways to improve, and as such, we’re thrilled to announce a series of new features designed to streamline your processes, boost efficiency, and provide you with provide you with more insight into your manufacturing operation. Let’s delve into the latest enhancements:

Ad-Hoc Shifts for Flexibility

In today’s manufacturing landscape, flexibility is crucial. Some factories require production outside of standard operating hours, often categorised as “Overtime” shifts. Thingtrax has now introduced “Ad-Hoc” shift functionality, allowing you to activate shifts as needed and deactivate them when they’re not required. When deactivated, these shifts have no impact on TEEP or OEE calculations. This means your operational teams won’t be affected by downtime they can’t control, and managers can accurately analyse true production time.

Crew Benchmarking for Efficient Shift Patterns

For factories with rotating shift patterns or crews, we’ve added Crew Benchmarking. With this enhancement you can assign crew names and factories. Then, map crew names to shifts and dates using the provided templates. With this information in place, you can select the crew and associated production values in the Analysis report, providing valuable insights into your crew’s performance.

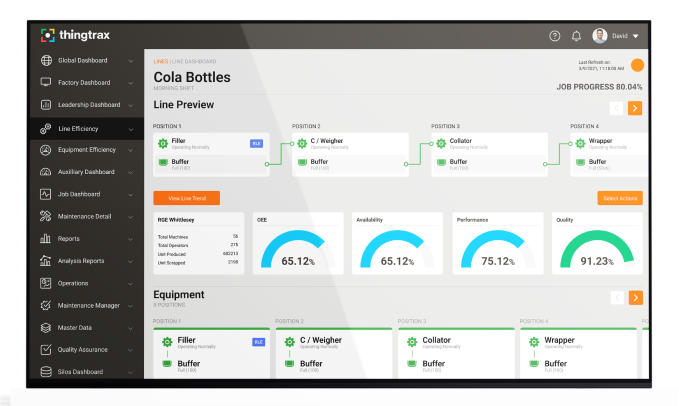

Reporting in Packs, Cases, and Pallets

Thingtrax now offers the ability to report production in packs, cases, or pallets. These quantities can be entered on the job card for the line, uploaded via CSV in the portal, or directly from your ERP system. Define the quantity of individual units in each container, and Thingtrax will automatically populate this information for future production runs. These fields are flexible and not mandatory, allowing you to choose the level of detail you need. Additional metrics have been integrated into the analysis suite, enabling more precise reporting.

Job Document Upload for Enhanced Documentation

Documentation is vital in manufacturing. Thingtrax now allows you to upload documents against a job, such as Standard Operating Procedures (SOP), quality plans, or images. These documents are securely stored by Thingtrax and automatically retrieved for the next planned production of that product, ensuring seamless access to critical information.

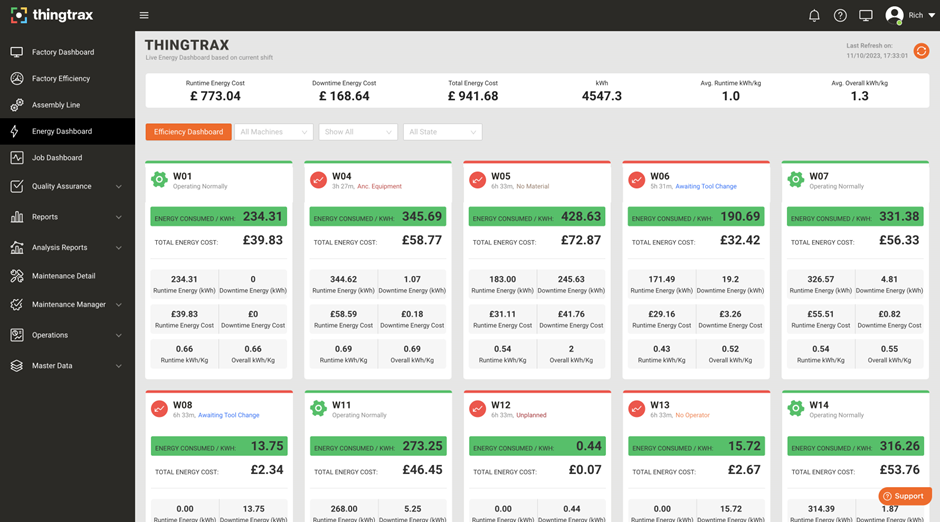

Downtime Energy Metrics for Cost Savings

We understand the importance of managing energy consumption especially during downtime. Thingtrax introduces Downtime Energy Metrics, enabling you to quickly identify energy consumption during downtime states. This empowers your operations teams and managers to reduce energy costs when production activity is not required. View these reports by both “Downtime kWh” or “Downtime kWh Cost” from the drop-down menu. The energy dashboard now visually indicates equipment uptime and downtime states, providing real-time insights.

Enhanced C-suite Dashboard Metrics

Our commitment to providing you with valuable insights extends to the C-suite. We’ve added several new Key Performance Indicators (KPIs) to the C-suite dashboard, allowing executives to make informed decisions. These additional KPIs include:

- Energy Cost Per Hour

- Energy Cost Per Unit

- kWh Consumed Per Hour

- Planned Downtime Events

- Total Planned Production

- Total Production

- Total Rejection

- Unclassified Downtime Duration

- Unclassified Downtime Events Percentage

- Units Per Available Hour

- Units Per Hour

- Units Per Run Hour

These metrics offer comprehensive visibility into your manufacturing processes, enabling your leadership team to make data-driven decisions for improved efficiency and productivity.

Energy Tracking for Lines

We’ve introduced energy tracking at the line level. Now, the total energy consumed is visible on the Energy dashboard, providing you with a clear overview of energy usage for each line. This enhanced tracking empowers you to monitor and optimise energy consumption, contributing to cost savings and sustainability efforts.