Meet Thingtrax at IFE 2024

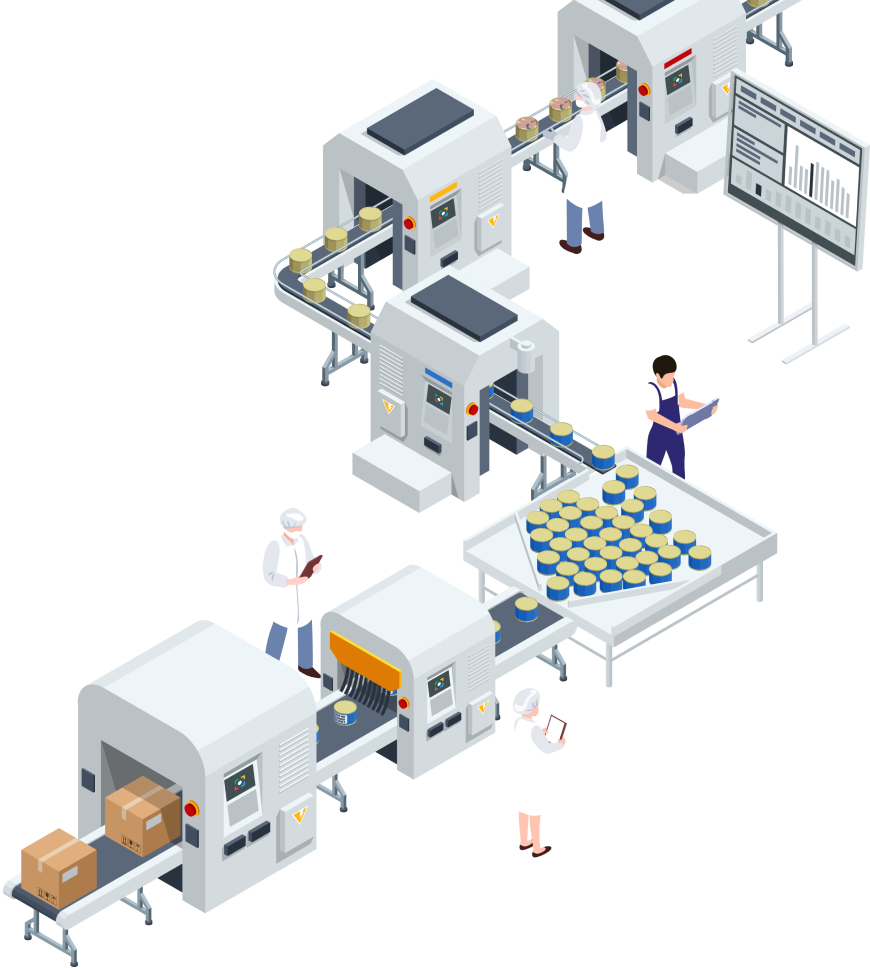

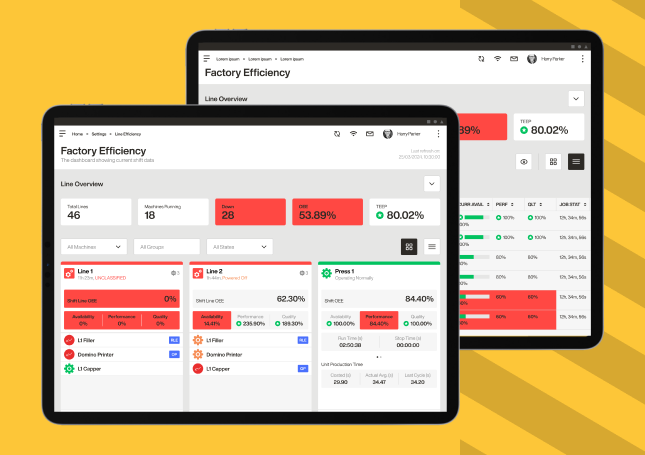

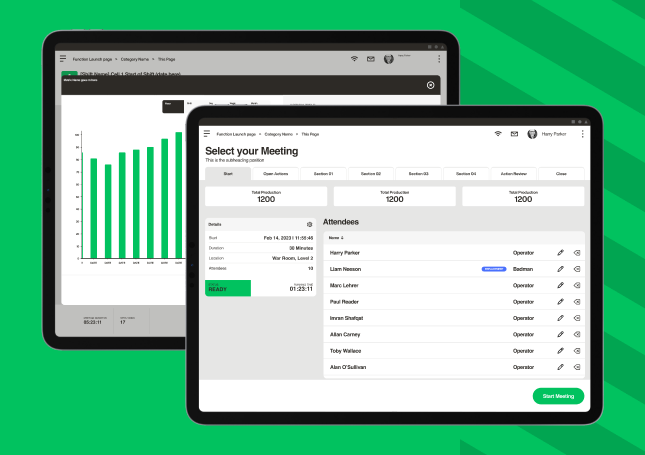

25-27 March, ExCel, London Experience the future of manufacturing with Thingtrax at Stand 501, IFE Manufacturing Expo. Transform your production line with Thingtrax’s innovative solutions, specialising in shop floor data capture and vision systems. Meet our experts and unlock the potential of real-time data analytics to optimise efficiency and ensure product quality at every stage […]